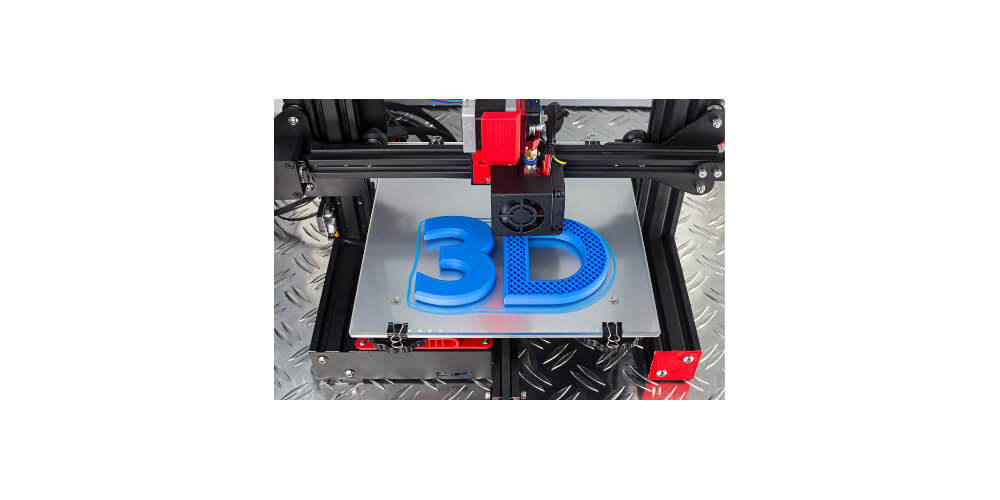

In the world of prototyping, everyone kept looking for a way to make things faster and better. Then, 3D printing burst through the doors with rapid prototyping.

The groundbreaking invention of the 3D printers and their working principle kept the world in utter shock for a while. just like JGMaker, you might be interested as well.

Rapid prototyping started using the principles of industrial prototyping. The purpose was to speed up the early production stages. There was a need for a faster and more efficient way to develop prototypes.

This need led to the invention of 3D prototype printers. It prevents unnecessary time wastage, saves money, and ensures that the product will be of superior quality.

Though people tend to overlook certain aspects of prototyping, it has the widest application of 3D printing in this era. And it is bound to stay this way for a while.

Over time, the 3D printing world has quickly spread to many parts of the workforce. What are some of these applications? Here is a breakdown.

The Applications Of 3D Printing

1· Medical and Dental Sector

Among others, the medical sector adopted the use of 3D printing early in its realization. This was easily accepted since the customization ability of the printing process was needed.

The personalization and customization ability of 3D printing was needed, for educational, and on-the-job purposes. 3D printing has continued to improve people’s lives until now.

In the related dental sector, dental industries use 3D printing to make patterns for casting dental crowns. 3D printing is also used to produce tools for dental aligners.

Patient-specific products, hip implants, and implants also get to benefit from the acceptance of 3D printing into the medical sector.

2· Automation Technology with 3D Printing

An early recipient of rapid prototyping was the automation industry. A growing number of automation industries have not only adopted but developed their manufacturing processes to fit 3D printing.

Numerous automation companies now see 3D printing as a way to produce vehicle spare parts on demand for after-sale purposes.

3· Food

A lot of people are getting excited about the acceptance of 3D printing into the industry. No, there will not be plastic food. Maybe just a little. 3D printing comes mostly in the food presentation part.

The way food is presented has continued to change over the years. With 3D printing now accepted, there are bound to be changed in food presentation.

Some foods are now 3D printed though still under consideration. It has been tested with chocolate and even meat. In more recent times, pasta is been researched.

4· The Fashion Industry

Clothing accessories made with 3D printing have walked into the fashion industry. With shoes, bags, hats, and headpieces made by a 3D printer, different fashion venues around the world should be ready.

They will have the feel of what a mix of technology and fashion feels like. A few fashion visionaries have included 3D printed runway designs in their collection as well.

Conclusion

In a big world full of great minds and daring ideas, 3D printing is nowhere near its peak. There is still a lot of space to cover.