Computer Numerical Control refers to a programmed code. The code represents instructions that control the precise movements conducted by machines or parts, such asCNC machine milling parts. The code controls how virtual objects can get automatically transformed into physical ones. In this post, we discuss essential terms used in CNC technology, in particular, CNC milling.

What is CNC machining?

CNC machining is a computer-centric and high-precision production or manufacturing technic. The term CNC is an abbreviation for Computerized Numerically Controlled.

In this method of manufacturing, the machines or tools used are controlled through computer programming. Doing so provides them with high precision. The tools get controlled using various axes, usually between 3 to 6, depending on the machine’s type and brand.

Other than 3D printing, CNC machining is the only other technology that allows makers or engineers to produce a physical part by designing a model using a computer. The model is known as a CAD model.

However, unlike 3D printing, CNC machining is a subtractive method of production. This means that raw material is placed on the machine table, and small chunks get eliminated to produce desired results. It is worth noting that this production method got first established between the late 1940s and the early 1950s. There are several types of CNC machining services, one of which is CNC milling.

What is CNC milling?

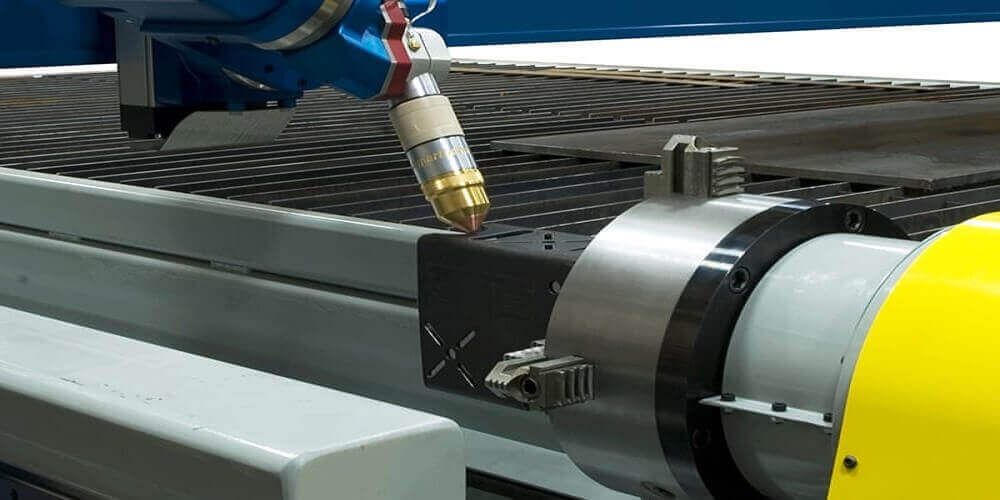

This process uses rotating and multi-function cutting mechanisms to remove materials or pieces from a workpiece.

What is a CNC milling machine?

Milling is the process of cutting or drilling through the material to come up with a pre-determined part or design. As mentioned earlier, CNC milling is a type of CNC machining technology. Therefore, a CNC milling machine is an automated cutting device whose tools or parts are controlled using a computer through programming. Like a regular milling machine, this device cuts and drills into a material like wood or metal to form a part.

The difference between a standard mill and CNC mills is that the latter uses automated and programmed instructions within a computer. Therefore, it provides more precision, better ability to perform repeated tasks, faster production, and better product quality. Another benefit of CNC milling machines is that they can cut in different angles since the cutters move in various axes. This is only possible through CNC technology.

What is a Computer-Aided Design (CAD)?

CAD is a type of program that allows you to digitally design a product or parts you want to produce physically. The virtual part can get produced through milling or 3D printing. It uses G-Code.

What is G-Code?

G-code refers to the code language that is applied when programming the CAD. The G-code instructs the CNC machine on how to transform the virtual product into an actual one.

Conclusion

The terms mentioned above are only the primary terminology used in CNC machining or CNC milling technology. They are meant to give you a starting point. However, you may want to look into several other terms and processes if you want to better understand CNC technology.