Whether you are making custom CNC parts at your workshop or outsourcing to an overseas company, you need to know the cost of CNC machining parts. You should also note that your cnc parts can be machined in a cost-efficient way. Are there cheaper materials that can be used? Can you find materials that allow easy machining? These are some of the issues you should settle at the rapid prototyping stage before proceeding to mass production.

To determine the cost of CNC machining parts, there is a need to understand the factors that determine the cost. In this way, you can know how to reduce the cost. In manufacturing, the best solutions and reasonable cost can help you finish your project within a short lead time. The following are the factors involved.

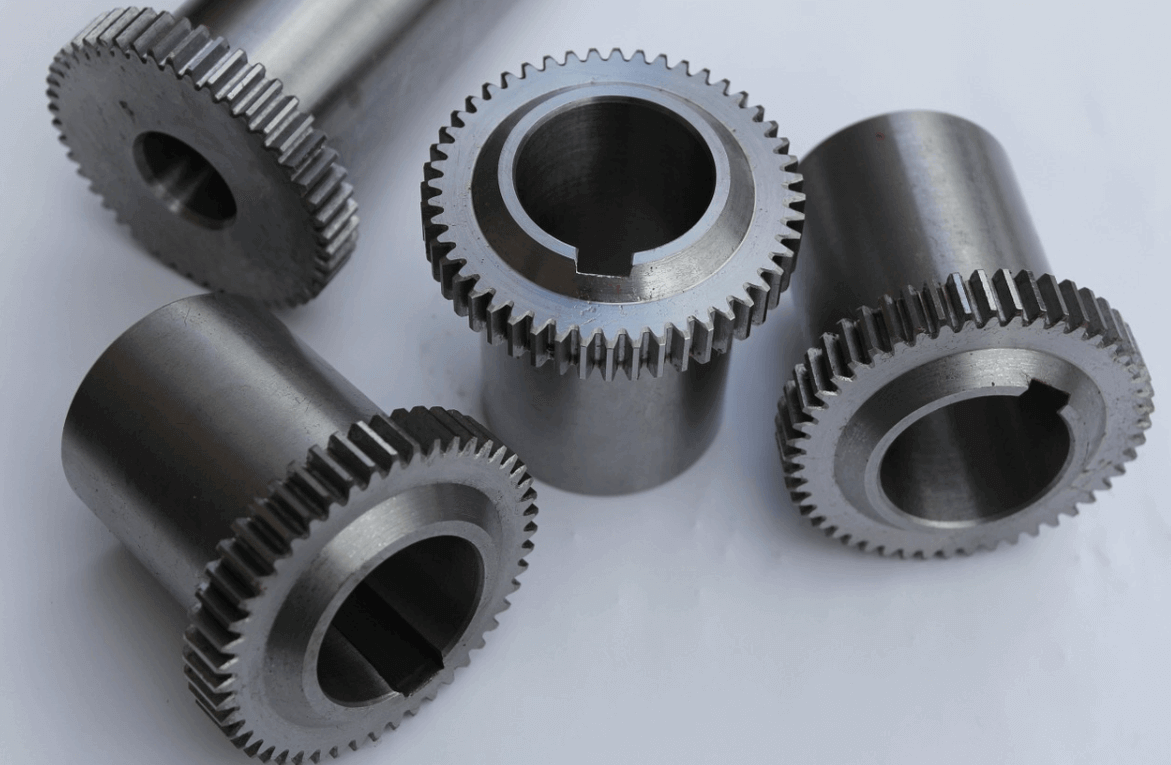

Material Selection

The type of material you use to make CNC machined parts determines the manufacturing cost. That is because some materials are difficult to process. For instance, the cost of machining carbon steel is higher than aluminum. That is because steel is machined at a slower speed than aluminum, whether you are using advanced technology or modern materials. High hardness materials such as tungsten carbide or steel wear away easily because of costly consumable tools.

If you request a factory that offers CNC machining services to process hazardous or flammable materials, then be ready to pay more for extra safety precautions. Therefore, there is a need to select the right material.

Design and Dimensions

The truth is that CNC machining geometry design and dimensions are crucial factors in CNC machining parts. Ideally, the larger the part, the more material it requires. On the other hand, components with complex geometric designs come with a higher machining cost. Complex products require tight tolerances, rapid tooling, and advanced surface finishing, which increase the cost. You may be surprised to learn that you can easily design parts that are difficult to manufacture or too expensive to make.

Type of CNC Machines Used

You should note that there are different types of CNC machines. Therefore, the cost of your CNC parts is dependent on the machine used. Some components require multiple machines to make. How many operations and machines are required? Remember that modern manufacturing and processing equipment is quite expensive, and the cost can vary depending on the brand, size, quality, and randomizer types. You need to consider all these factors when minimizing CNC machining parts cost.

Number of Parts

The number of components or parts you produce determines the overall cost of the CNC machining service. Since these parts need different manufacturing processes and operations, when several parts are being made, the cost increases.

Additional Processing

Most CNC parts need extra processing like surface treatments, specialty coatings, and heat treatment. The additional processes increase the cost of the product. Therefore, you should evaluate different processes and treatments and determine whether they are necessary.

Inspection Standards

There is a need to check the permitted tolerances. Parts that require tight tolerances are expensive to produce. Also, industry inspections of custom CNC parts, especially those used in high precision situations such as oil and gas, aerospace, and transport are difficult to make.