Precision machining is used to create parts and components of several items and tools, used by people to get by every day of their lives. When it comes to technology, precision machining tends to uphold companies whose visions are channeled towards providing efficient technologies and hardware that supports developments.

Have you been hearing of precision machining? Are you confused about what it is? Would you love to know? Then, stick to this read as you get to find exact answers to some of your frequently asked questions

Q: What is Precision Machining?

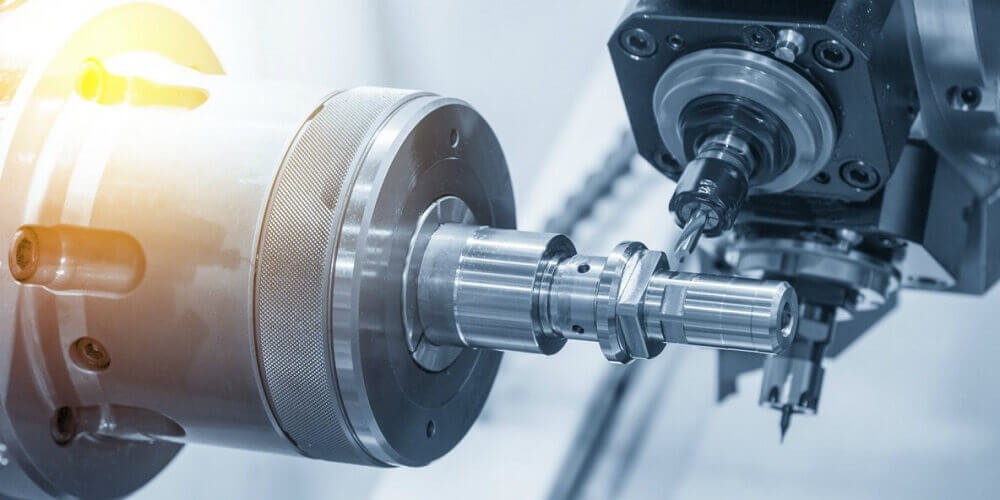

A: Precision machining is described as a process of removing deductible raw materials from a specific workpiece. This is done while keeping close-tolerance finishes together to form a final product. In other words, precision machining is the act of creating large pieces of raw materials into smaller, precise forms, usually to meet some accurate specifications.

Q: What Should I Consider When Choosing a Precision Machine Shop

A: the first thing to consider while seeking a good precision machine shop is the quality of service and production. If the quality is great, then you can expect to get an accurate delivery at the end of the day. There are people who consider prices first. While this is still good, you must understand that working with a supplier who is committed to their work helps you excel in your business. Therefore, examine their technical expertise and ensure that everything is in good shape first before making a final decision.

If the supplier has been able to retain a lot of old clients, then it’s also an indication that you should hire their service.

Q: How Does Precision Machining Function?

In precision machining, engineered tools, custom software, and certain steps are employed alongside raw materials like ceramic, plastic, and metals to form specific beautiful products. It often goes through instructions assigned by computer aided manufacturing (CAM) and computer aided design (CAD). If the tolerances are tight, these computer programs help to improve the ability of the machine to meet them.

Even though a lot of designs come out as computer aided designs (CADs) and engineered, many tend to begin as hand-drawn ones in their initial stages.

Q: What Materials and Tools Are Used During Precision Machining?

There are quite a number of raw materials that be used during precision machining. These raw materials may include hit not specific to:

- Metal

- Ceramics

- Steel

- Composites

- Graphite

- Bronze

- Glass

- Plastic

To create accurate cuts and detailed subtraction of raw materials, different combinations of tools are used sometimes. The tools used in the process may vary and it’s mostly dependent on the raw materials used for production. Some tools that are used frequently include:

- Lathes

- Milling machine

- Electric discharging machine (EDM)

- Grinders

- Saws

Final Thoughts

As mentioned earlier, precision machining s part of the most important processes of creating items in their large and small parts. There are precise manufacturing specifications and guidelines that most suppliers use to ensure that the quality of products is achieved.