the operation of an ARC valveAn automatic recirculation valve (ARC valve) is referred to as a multifunctional valve with the primary purpose of ensuring that a pre-determined flow is assured in a centrifugal pump. Therefore, it can permanently be destroyed if run dry. Here are key points about the operation of an ARC valve, including crucial points that a professional needs to note about the device.

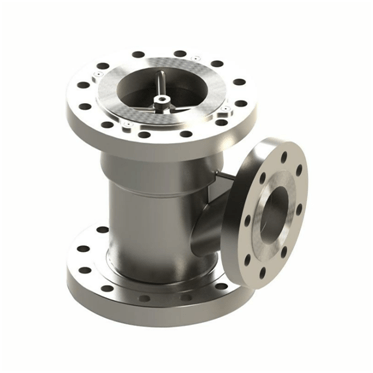

1. ARC Valve Design

The standard automatic recirculation valve has a unique design specifically created to endure stimulation. It has been perfected through research and extensive analysis by professionals. Automatic recirculation valve manufacturers have also customized designs for unique process demands. Meaning, there are ARVs perfected to serve in severe operating environments.

2. Power Overview

The power sector has been looking for new techniques to develop energy resources. Such industries seek to build power efficiently. This will help to meet the rising power demand. It’ll also have minimal effects on the environment. Automatic recirculation valve can assist clients in overcoming such challenges, especially in coal power generation.

3. Supporting The Production Of Oil And Gas

There’s a rise in demand for hydrocarbon. This hurts established reservoirs. As organizations face extended rig times, precarious environments continue to develop. There’s a need to navigate through networks to stabilize the environment. Automatic recirculation valve supports the downstream process that involves refineries as well as processing plants. The operations need various valves to support the production of final products.

4. Operation Of Minimum

The automatic recirculation valve is responsible for protecting centrifugal pumps. This is during a low load operation. When the ARC valve pumps load drops below a specific preset flow rate, the disc of the valve gradually moves toward the seat. This causes the bypass icon to open a flow of path. The lowest flow rate is then maintained.

5. Applications Of Automatic Recirculation Valve

Some of the typical applications of the valve include protecting pumps that handle hot water, particularly for boiler feeding and cooling water plants. This may involve where partial water evaporation content can dry the pump. The valves enable water circulation without damaging the pumps.

6. Operating Conditions – Combined Flow

By the time the flow initiated by the process is reduced, pressure on the disc spring is gradually lowered. This allows the disc to move towards the seat. The check valve of the automatic valve moves to an open position where there’s partial flow to the main outlet.

7. The Operation Of The Centrifugal Pump Protection Scenarios

Centrifugal pumps often transform the valve’s mechanical energy into existing pressure energy through the centrifugal force. As a result, the impeller will start rotating in the fluid of the pump. For you to avoid overheating, the pump needs some minimum liquid flow. If the flow isn’t maintained, the valves can be damaged.

8. Main Functions

The rising demand for modern industrial processes has contributed to the need for higher pressure in different manufacturing plants. Consequently, the need for pressure has then created a demand for centrifugal pumps that have high heads. But, such pumps have slightly lower tolerances, thus making centrifugal pump valves more sensitive. The nature of the flow control system demands some essential functions, including protection against the pump overheating and the ability to build the pressure to attain hydraulic balance.

Take Away

Centrifugal pumps are the most common pieces of any processing equipment. In an automatic recirculation valve, there’s a requirement for flow conditions to be in a position to meet the process requirements. That’s why it’s essential to understand the entire operating system and technique of the machine.