The performance of magnets such as Neodymium varies across due to the effects caused by various factors. These magnets are widely used for multiple applications, are strong, and have good magnetic properties. More information is available about the Neodymium magnets, and you can click here to read. Generally, all magnets possess a pull rating which is calculated in kilograms. Since there are no perfect conditions for them to work in, their performance is affected differently. We expound on factors affecting magnet performance below.

Factors Affecting the Performance of a Magnet

The factors that affect the performance of any magnet include;

1. Material

Magnets attract metals of different materials hence the effect on their performance. The material they attract determines its magnetism conduction or pull strength. The pull strength is tested using mild steel, which acts as the contact material. Other metals like cast iron or alloys of steel and not used as their power to conduct magnetism is low compared to that of mild steel. They prevent the magnet from reaching its maximum capability. Some metals reduce the pull while others increase it hence the performance effect.

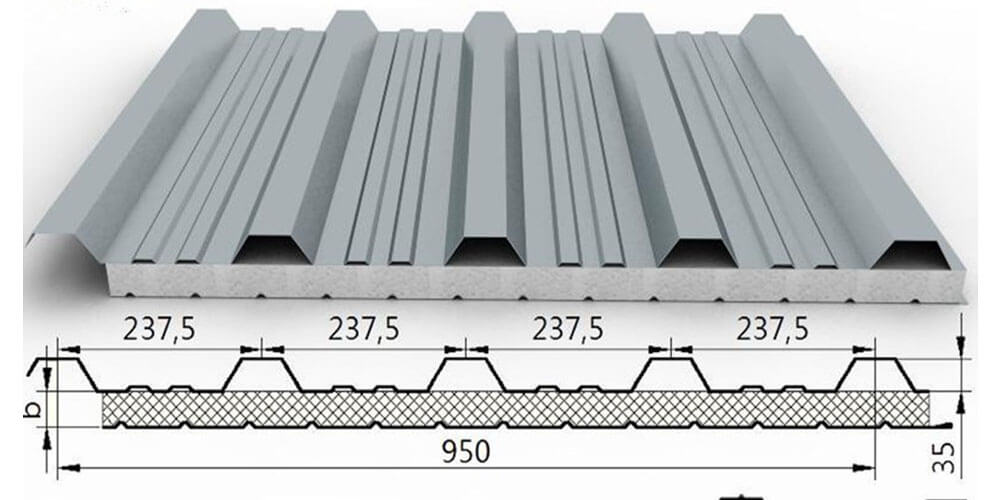

2. The thickness of the steel

A steel surface affects the performance and pull of a magnet. The thickness of the steel must match the magnet’s requirement for it to perform at its maximum and take in all the magnetism. If the contact steel isn’t thick enough, say 1mm, when the required thickness is 10mm, the magnet will not attract as needed and will deliver a fraction of its potential capability.

To test and ensure the steel thickness is okay, attach another piece of steel onto the previous one. If the extra steel piece remains attached to the first one when you move the magnet, the steel cannot fully absorb the magnet’s power. If it falls off, it indicates the steel thickness is correct, and full magnetism absorption is taking place.

3. Temperature

Any magnet used in conditions above its maximum operating temperature range tends to lose its performance completely. The maximum operating temperature varies between magnets. For example, for Neodymium magnets its 80 degrees centigrade, while for Ferrite is 180 degrees centigrade.

If you subject the magnet to very high heat severally, the performance reduces. Magnets have magnetic domains that are aligned; hence they possess magnetic properties. When the domains are misaligned, like in the case of constant heating, they lose their magnetism and can not function as expected. Alternatively, low temperatures are ideal for magnetic performance. When exposed to such, their performance increases.

4. Corrosion

Corrosion mostly takes place in the presence of water. Since most magnets are used outdoors, they are prone to this, causing their performance to decline. The magnet’s plate is damaged, resulting in rust; hence the magnet loses its magnetic power. However, some magnets are designed to withstand such conditions such as Samarium Cobalt.

Conclusion

When buying a magnet, you expect it to have and maintain its original properties during its use; however, sometimes, that’s not the case. The factors above will help you understand what affects it and prevent such exposure to these elements. Take note of them to keep your magnet in its maximum magnetic capability.