Prototyping is a vital stage in the manufacturing process. However, people prefer foregoing this sage and jump straight to the final product without realizing the importance of it. A prototype is a rough draft of a part of a product. A metal prototype is better compared to a plastic prototype in terms of functionality. Plastic prototypes are relatively cheap and are mostly used in the early stages of prototyping. Some manufactures may not require functionality in their prototypes; this is where plastic prototypes come into play since there is no reason to spend a lot of money on metal prototypes.

Why go for metal prototypes instead of plastic?

- Metal has a higher boiling point as compared to plastic. This means that a prototype made of metal will have a higher heat resistance level. If the final product is meant to face very high temperatures, using a metal prototype will ensure that the final product meets this standard.

- We all know that metal is incredibly strong compared to plastic. Industries like the aerospace and automotive usually use metal prototypes due to the nature of the final products. These prototypes are made of metal because they should be strong, just like the final product.

- Metal prototypes are versatile.

How to make Metal prototypes?

You can make metal prototypes through;

- CNC Machining

- 3D Printing

- Sheet metal

- Metal casting

- Metal extrusion

CNC Machining

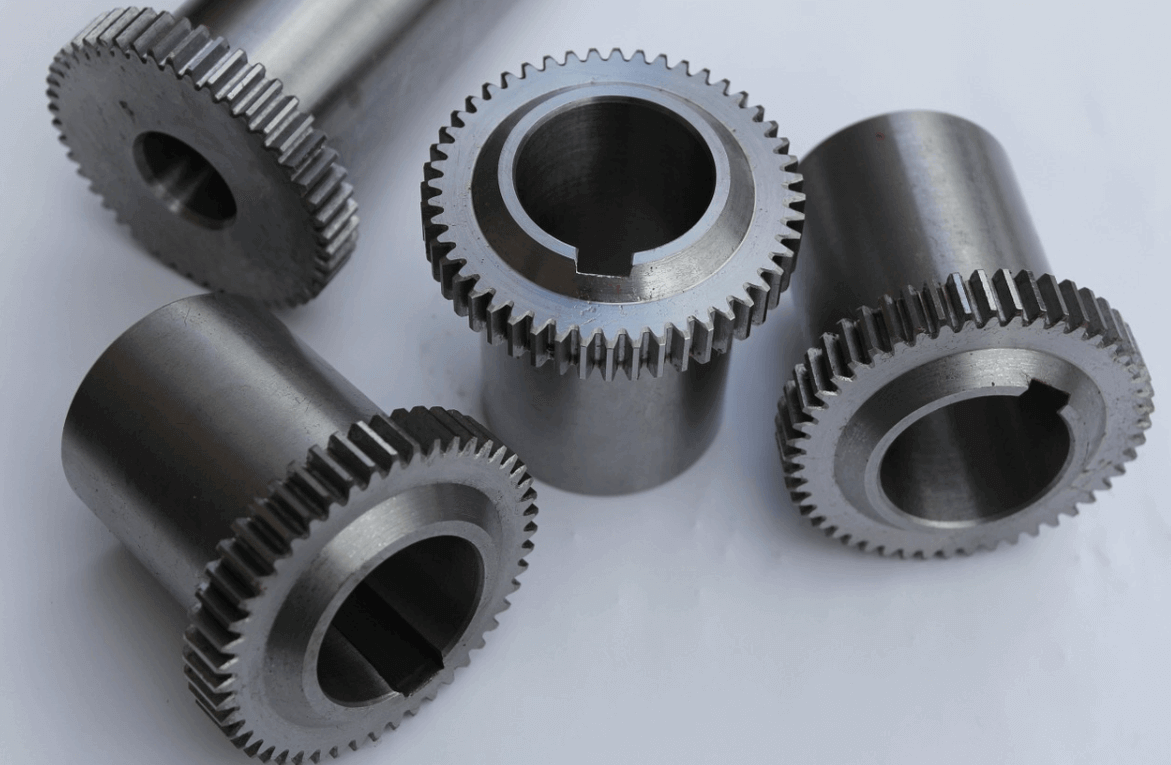

Metal machining is the most commonly used method of prototyping since it is relatively affordable. To develop a metal prototype, a CNC machine is guided by a computer program to carve it out of a metal block. This process is effective and ensures quality products. The downside of this method is that a lot of waste is produced due to the process’s subtractive nature. Machining is cost-effective since there are no special tools and experience required.

3D Printing

Like CNC, 3D printing relies on digital designs to come up with a prototype. This allows easy shifting of designs and can be fairly affordable. The process may rely on selective laser melting technology or direct laser sintering. Compared to CNC machining, producing prototypes using 3D printing, the production cost is higher since metal additive manufacturing machines are expensive. On the other hand, the flexibility of the process allows you to change designs easily, making the production process efficient.

Sheet metal prototyping

These prototypes are made by cutting and folding of sheets of metal. The process is used to make parts such as brackets and industrial parts. This process may be expensive than other alternatives, where several tools are required.

Metal casting & extrusion

Under casting, liquid metal is molded to produce a metal prototype. On extrusion, the metal is passed through a die to produce parts with uniform cross-section. Metal bars and rods are usually made through this method. The problem with the two is that they require expensive tooling and do not have a wide variety of products.

Prototyping allows you to adjust the design and ensure that the final product reaches maximum quality. With metal prototypes, you can estimate the actual cost of producing the final product. Although people forego this crucial part of manufacturing, it has proven to be a requisite tool.