Rapid prototyping is a section of rapid manufacturing involving the fabrication of items using 3D Computer-Aided Designs. Rapid prototyping has several services under it used in a number of applications due to their many benefits. Product manufacturers prefer this process for custom machining of their products to the traditional manufacturing methods. It is quick, affordable, and saves time; hence customers can have their products finished and introduce them to the market within a short time. In this post, we look at the rapid prototyping classifications.

Classifications of Rapid Prototyping Techniques

The purpose of these processes is to produce prototypes. However, they all work differently, use varying materials and create different prototypes based on their fidelity.

1. Solid Based Process

It is divided into two that is fused deposition modeling and laminated object manufacturing.

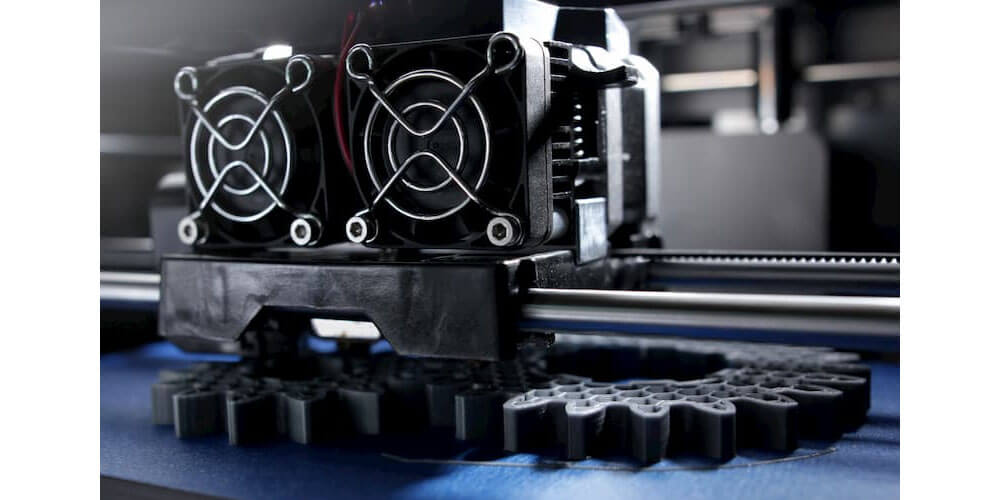

Fused Deposition Modeling or FDM involves three-dimensional printing technology and features a filament. The filament is usually thermoplastic and is subjected to heat until it melts in the nozzle barrel. The barrel is located within the printing machine, so after melting the filament material, its molten form is deposited systematically in layers following instructions from the computer deposition program. The use of this process is popular with desktop printers, and it’s also time-saving and affordable.

The laminated Object Manufacturing process is also referred to as sheet lamination. The feed mechanism carries a layer of paper or plastic to the construction surface for cutting using a laser. The paper layer forms more layers which are pressed on by a heater roller to help them bond together. Later, computer-controlled laser beams cut the layers into the desired shape to create a CAD design pattern. It is also quick, cost-effective, and easy to use.

2. Liquid-Based Process

Stereolithography (SLA) is the primary method used in this process. It is the most common for industrial applications and incorporates the 3D printing technique among all the rapid prototyping techniques. It creates different parts, especially plastics using a solidified photosensitive liquid passed through the computer-aided ultra-violet light to form layers. The layers stick together using self-adhesive materials to form a 3D object.

3. Powder Based Process

It consists of two techniques: Direct Metal Laser Sintering and Selective Laser Sintering.

Direct Metal Laser Sintering is primarily used with metals and their alloys. The metal is subjected to very high heat from the laser to below melting point through the laser sintering or to a level above the melting point through selecting laser melting. The formed powder is fused into a solid layer, and more layers are exposed to make the process continuous. However, compared to other techniques, this one can take hours or days to complete.

The Selective Laser Sintering method forms parts by adding layers of materials using the additive manufacturing technique. A laser lays the material, then heating and sintering are done to develop the prototype. However, additional processing goes on to smoothen the surface.

Bottom Line

Rapid prototyping is essential for prototype creation which facilitates the development of the final product. All its techniques have advantages and disadvantages and are suitable for different applications in the manufacturing industry.