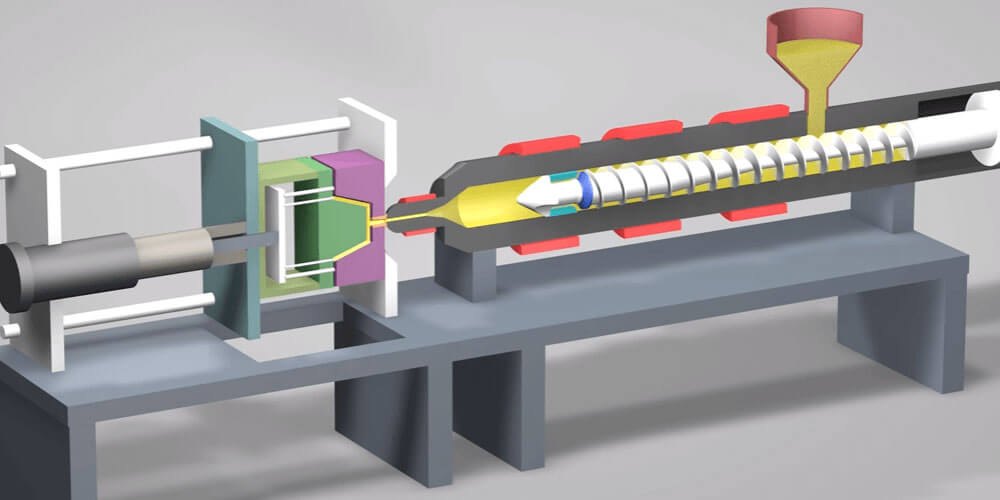

Injection molding is one of the most popular manufacturing processes in existence. It is highly used in the mass-production of plastic parts, and the process involves the use of an injection molding machine, also known as a press. The popularity and success of this method have led to a lot of injection molding companies being established. In this excerpt, we look at considerations for injection molding.

Things you need to do before producing parts using injection molding

Before you start using this technology to manufacture parts, below are some things you should consider;

1. Finances

The financial considerations are perhaps the most significant. Note that you need to account for the entry costs, production, and design preparation costs. It would help if you accounted for the costs of entering into this industry. This may include the cost of purchasing the materials and the machinery required. At the same time, you ought to determine the number of parts you want to make and how much it would cost to get the materials and complete the production process.

When planning for financial responsibilities, most people forget about the design process. The design process can be split into two categories. These are the part and tool design categories. Each of these processes requires money to complete. When considering all these financial elements, you need to also think about how much profit you will make. The last thing you want is to spend too much money in the process and not make any profit in return.

2. Designing

Next to the financial considerations, the design considerations are also essential. Creating the design is perhaps the most critical part of the process of injection molding. The part design will influence the overall outcome of the production process. When designing the piece, you should have injection molding in mind. It would help if you simplified the geometry and minimized the number of parts when designing the part so that the production process is easy.

The design of the tool is also essential. It would be best to make sure that the mold tool design is free from any defects to prevent production issues. Note that the presence of defects during production could cost you a lot of time and money. Therefore, you need to take your time during the tool designing process. Naturally, you will need an expert team for this part of the process.

3. Production

After designing the part and the tool, the next natural step is production. Note that plastic injection molding is an automated process. This means that it does not depend on a lot of human input. This means that once the machine is set up and the raw materials are fed, the rest of the work is done automatically. Therefore, to ensure that the process runs smoothly, you need to ensure that the machine is set up correctly. It would help if you were careful in the assembly process.

Conclusion

The injection molding process is not as intricate as most people assume. The production process itself is pretty easy because it is automated. However, the challenging part is designing the tool and the desired part.