Turning is one of the oldest manufacturing process, the traces of which dates all the way back to ancient Egyptian civilization. The purpose of turning is to create intricate and detailed parts, pieces, or components of any machinery. Thanks to lathe machines, the turning process has come a long way from manual turning to program-run CNC turning.

Using a turning lathe, the latest technology, and skilled machinists- CNC manufacturing service providers can now create custom-designed parts and components (also called workpieces) to the exact requirement of the client.

Another very popular CNC manufacturing process is CNC milling, and people often think of milling and turning as the same thing, but that’s not true. CNC turning and CNC milling are computer-run machining processes, but they serve two different purposes.

CNC Turning Vs CNC Milling

Both the CNC Milling and CNC turning process basically have the same purpose of making intricate and accurate parts and components that are very difficult to create by hand. And, both CNC Milling and CNC Turning do use computer codes written in G-Code language, but there is a very obvious difference in the workings of these two processes.

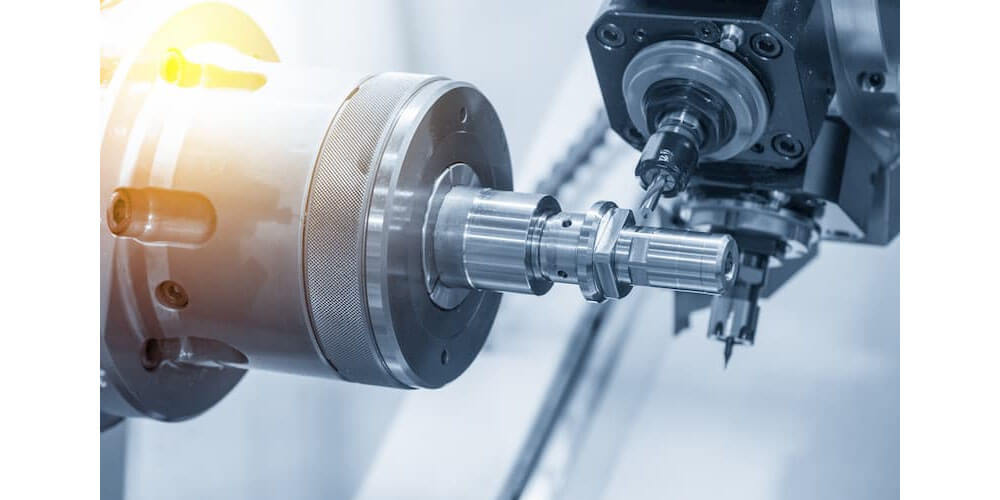

With CNC Milling, it is the cutters that move around the workpiece on different axes to morph the final product, whereas in turning, the cutters are rigid and parallel to the moving workpiece. Another difference is that CNC Milling is mostly to provide the final touches to the workpiece, for example, adding intricate cuts, holes, etc. Whereas the major use of CNC Turning is for making cylindrical parts from scratch.

CNC Turning Process

Whether you choose CNC Milling or CNC Turning to manufacture your parts, there is a certain process that you need to follow before your CNC manufacturers can start the manufacturing process. The following FOUR steps will put you on the right track to start your CNC manufacturing process.

- Making a blueprint of your component in CAD(Computer-Aided Design).

- Converting the CAD blueprint into G-Code.

- Setting up the lathe.

- Starting the manufacturing process.

Types Of CNC Turning Process

Just like every other CNC manufacturing process, turning also has a lot of other types to prepare different types of parts. Because the turning process has wide applications, there are lots of types of turning. Here are some of the most common CNC turning processes.

- Straight Turning or Roughing: The most common form of turning that cuts any extra material from a workpiece to develop a cylindrical piece with a uniform diameter.

- Taper Turning: Taper turning also is for creating cylindrical shapes but with the difference in diameter. Taper turning is when the cylinders need to have a decreasing diameter.

- Spherical Generation: To prepare the perfect sphere, manufacturers use the Spherical Generation turning process.

These THREE turning processes are the most common in the industry; however, these do not provide the finishing touch to the workpiece. For the finishing touches, the turning lathes provide FOUR more processes depending on your parts and the type of finish you need.

So, even though all these processes are different from each other, using only one will not give you the desired results. To get the best out of CNC Turning, you will have to go through TWO or THREE steps.