For any part to be termed a machined part, it is obvious that the article has been worked on with a machine. The process of machining is done usually by cutting materials into the desired shape.

In many countries around the world, there are different level of progress that has been made with regards to machining practices. Doing rapid prototyping China will prove the extent of progress.

Machining is usually done on metals. Using any machine tool, the metal is cut or filed into the shape and size required. This is usually controlled with a material removal process.

Machining is used to manufacture a lot of metal products, but it is also used on materials like wood, ceramics, composites, and plastic.

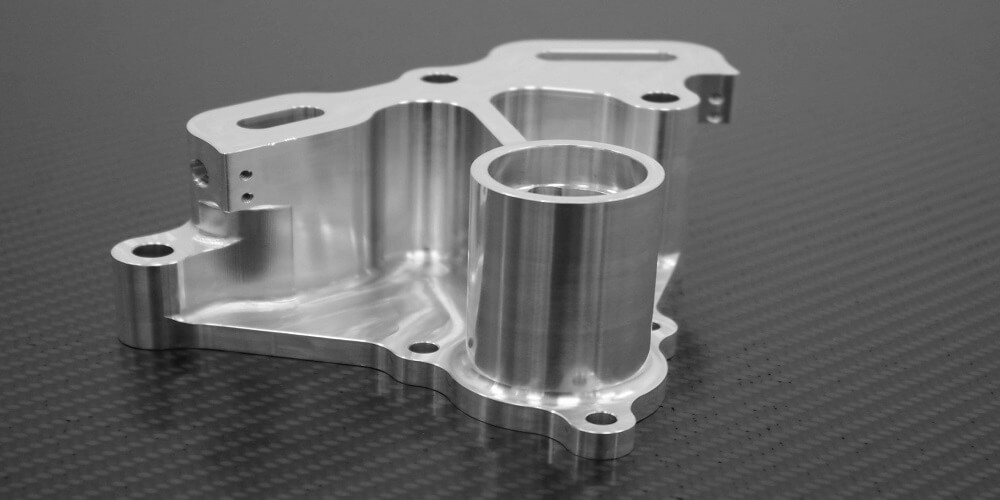

Machined Parts

These are items that people make use of in their day-to-day life. A lot of people depend on these items in their dad to day activities.

Some machine parts include some complicated designs. These designs could be used to make household devices or utensils. Others are used as a tooling surface or for spare part replacement.

Some machine parts are made industrially for industrial purposes. Others are not. That is why people in the world can be said to be dependent on machined parts.

In creating a machined part, after the raw material has been cut to the desired shape ad size, it is then worked on with the material removal process. This helps to tune the metal according to specification.

Machining done with any material removal process is popularly known as subtractive manufacturing. This type of manufacturing process is achieved by cutting bits of a part to form the desired shape.

Facts About Machined Parts

Guarantee Quality Accurately

Machined parts are dependable. This is certain because the manufacture of these parts is done using CNC technology.

You can be sure of its dependability because of the aspects of machining accuracy that are well known to be delivered by CNC machining to all its parts.

Everyone knows that tolerance is unavoidable since there is an allowable range. Yet, the design has continued to improve a time passes.

Time Effective

Many machined parts have a certain feel and look when it is achieved using CNC machining. These machined parts are especially pre-engineered to make assembly of the concerned parts easy.

Since the machining process has made the assembly easy, the assembly of these parts will take less time and increases the productivity of the team working on it.

Application Of Machined Parts

There are numerous applications of these parts. They have been used to make customized tools and parts.

Others are used in highly sensitive areas like aeronautics and aerospace. The precision level is what makes it accurately the best fit for the job.

CNC machining processes have made it possible for machine parts t be formed from almost any material. This explains why there are so many parts formed from different manufacturing materials.

Millions of engineering plastics are machined. These parts are processed using advanced CNC machining. The advanced CNC machining has detectors. These detectors are there for quality assurance purposes.

Conclusion

Even though it can be easy to ignore, machined tools are always there in our lives. These parts almost always have very detailed, accurate, and precise parts.