Are you looking for a company to provide you with faster and economical metal finishing services? Inovatec Machinery is right here to serve. Over the past decade, the industrial revolution of machines and mass production has led to increased use of metals in various industrial and home-based operations. That explains the current application of metal finishing equipment. For over 25 years, Inovatec Machinery, a China-based firm, has been at the forefront in the provision of quality metal finishing services.

Some of the metal finishing services provided include vibratory finishing equipment, centrifugal barrel machines, centrifugal disc machines, and other tumbling media types.

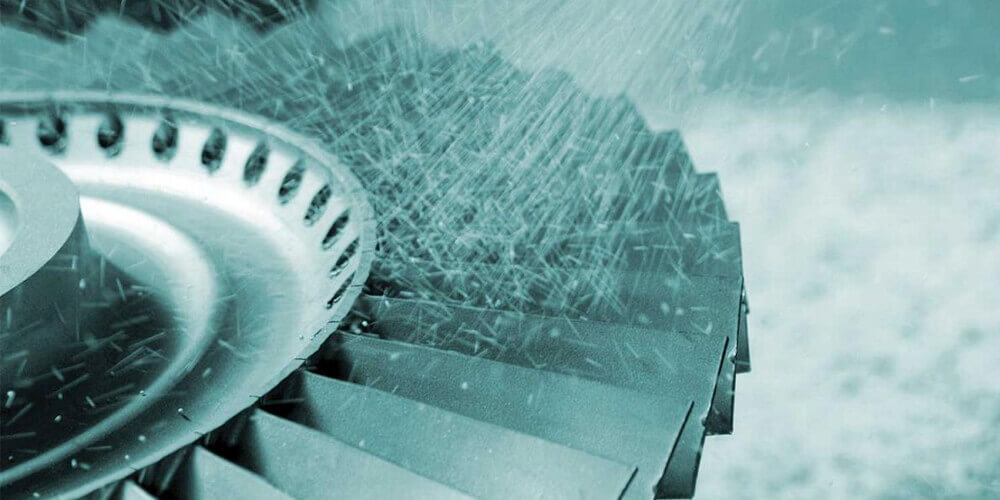

Understanding the Tumbling Media

Tumbling media, in other words, vibratory finishing media, primarily focuses on the following industrial processes in the scope of metal finishing; parts deburring, cleaning, polishing, burnishing, deflashing, and de-rusting.

Further, Inovatec Machinery, the tech-oriented company, has a full range of tumbler media which includes;

a. Ceramic tumbling media

This is perfect for metal parts that require deburring, edge-breaking, de-flashing, and rust removal.

b. Steel tumbling media

This tumbling media is primarily meant for burnishing casting parts, which aid in achieving maximum luster to add on aesthetic value.

c. Plastic tumbling media

It is applied to deburr aluminum machined parts. Essentially, it helps avoid lodging or tampering the surface of the metal.

Natural tumbling media

The primary purpose of the media is to brighten metals and plastics parts. However, this is done carefully without removing the material nor surface hardening.

Why Inovatec

1. Pricing

Inovatec is unabashedly proud of its ability to offer competitive prices. This is aimed at encouraging customers as their success is the success of the business.

2. Packaging

At Inovatec, the machines are not packaged just for the sake. The management provides high standard packaging often done through a wooden fumigation pallet. To illustrate this, the media packs 25kg or 50lbs.

After processing, they are put in one plastic woven bag. Additionally, if a customer purchases forty bags, they will be wrapped in one pallet. This effort is geared towards ensuring safe deliveries to customers. Besides, you can check the goods at any time before shipment. This creates some assurance of safe deliveries as well.

3. Method of Payment

Understandably, the company prides itself on providing customer-friendly payment methods. This is not only to encourage but also to save customers’ pockets. Typically, if a customer meets a 30% advance payment, the remaining 70% is paid before delivery is made. This is quite lenient. Further, a 100% spot letter of credit is also issued if a high volume of orders is made.

4. Quick Delivery

Typically, the tumbling media production cycle is 15-25 days. However, in case it is an urgent order, delivery can be done within two weeks. No delays.

Final thoughts

With 25 years of industrial experience, you can be assured of adequate and reliable support in choosing the right company for your finishing needs. The company serves a wide range of customers ranging from those who sturdy forgings, dealers of 3D printed parts, aluminum machining parts, and so forth.