Do you want pipes to boost the system in your homes? Then you would be interested in nickel alloy products of INKOS. They are the leading manufacturers in providing all kind of pipes solutions. You can get every type of stainless steel and nickel alloy products, such as nickel alloy pipes, etc. They have pipes, flanges, and fittings of duplex and super duplex, stainless steel, and nickel alloy.

Why choose nickel alloy piping?

They are a professional and legit company working since 2012 and supplying nickel and stainless-steel products to multiple manufacturers. They have a vast variety of top-class nickel alloy pipes and stainless-steel pipes such as Hastelloy C276, Monel 500K, Incoloy 800H, Inconel 601, Monel 400, etc. They have more than 300 tons of stocks in their warehouse, which is ready to be distributed.

The quality of their stainless steel and nickel alloy products are of the highest quality. They do proper quality checks, 100% inspection, and standard tests before delivering the product to the customer. They can deliver the order to customers within seven working days for standard size and work on the custom size of your order. They also offer you a 100% return if you face any problem while using their product. They also offer other services to their customers, such as welding, drilling, piping preparation, and slitting.

Fabrication Services

They offer you pipeline cutting, pipeline design, prefabrication management, and pipeline groove processing services. Other than these services, they also offer other pipe products related services such as pipeline flaw detection, anti-corrosion paint, welding, logistics, and other services to meet the customer’s requirements. The main advantage of availing their services is that they can prepare your pipes at their place instead of fabricating the pipes at the worksite. It will not only reduce your workload, but also it will be more convenient to manage and coordinate the fabrication and take care of the quality. It will also improve the on-site installation efficiency of the pipes and save your time.

You can also order pipes of unique materials such as titanium, Hastelloy, and other precious materials. But the fabrication of pipes using these materials needs more installation quality requirements. Constructing them directly on-site is more complicated, so it will be more beneficial if they are constructed at their place.

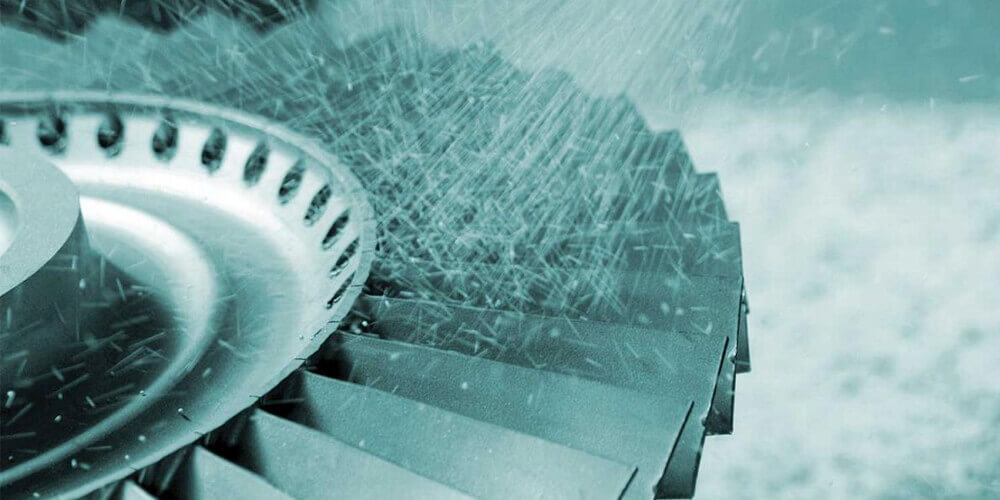

Laser Cutting Services

Are you looking for laser cut nickel alloy and stainless-steel products? You can get them for INKOS all piping solutions. They have a massive variety of laser-cut products to offer. They can laser cut in different designs and shapes to meet your requirements. No matter how difficult and complex the arrangement or shape is, they can laser cut it to fabricate your product. They have various laser cuttings samples displayed on their site to give you an idea about their laser-cut capabilities.

INKOS Fasteners

They have numerous bolts available for meeting your needs. Collection of their bolts include Hex Nuts, Hex Bolts, and Stud bolts. Their fasteners are made up of stainless or carbon steel of the best quality.

- Certified from Legal certification authorities

- Eco Friendly

- 24/7 customer service

- 100% return guarantee

- Large stocks of products of standard sizes available

If you are finding a company to manufacture your pipes or other similar piping services, you should go for an INKOS piping company.