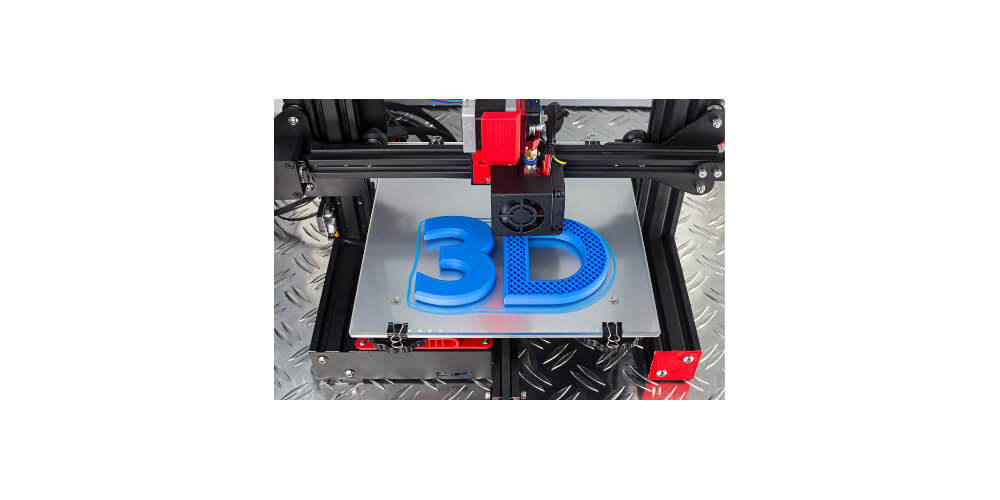

A desktop 3d printer develops three-dimensional objects from a digital 3D model through a process known as additive manufacturing. Successive layers of materials are laid to form an item. These printers are essential, especially to companies that use rapid prototyping. But note, these printers available depending on the level of expertise, i.e., from beginner to professional level. Today, they are being embraced by many since the 3D printing technology has revolutionized globally. In this extract, we look at the basics of a 3D printer.

Basics of a 3D Printer

a. How It Works

A 3D model is produced using CAD software and is then converted into STL format.The model is then sliced digitally, preparing it for printing. It is broken down into layers that are sent to the printer for printing. The method used will depend on the type of printer.

b. What Are The Types of 3D Printing Software

Various computer-aided designs (CAD) software use different file formats. Some of them include:

- STL-Standard tessellation language handles a single color and is used by most desktop 3D printers.

- The AMF-Additive manufacturing file format supports multiple colors.

- VRML-Virtual Reality Modeling Language can also handle multiple colors and is used by printers with more than one extruder.

c. What Are The Benefits of a 3D Printer

- Speed

The printers are known for rapid prototyping. They manufacture,.test, and design models very fast.

- Flexible Design

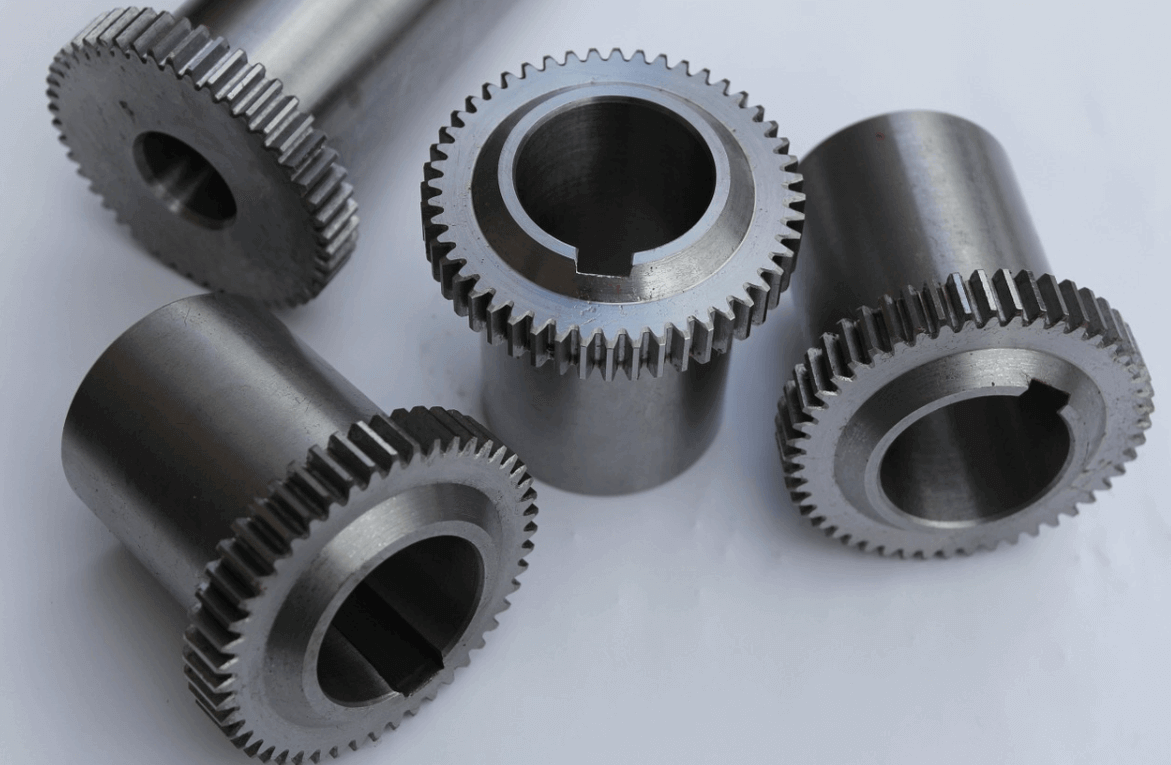

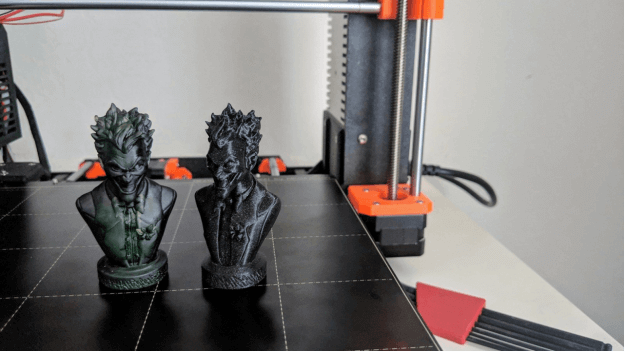

It is easy to create and customize designs, depending on your preference. They can be developed in various sizes, shapes, or colors.

- Minimal Errors

With 3D printers, objects go through one step during the manufacturing, and there is no interaction of the operator. Products underwent multiple stages with the traditional processes; hence many errors developed.

- Cost-Effective

The cost of labor, running machines, and materials is reduced. There’s no need for hiring workers as the devices are automated, and a single printer now does the manufacturing processes done by many machines. The 3D printers produce little to no waste; hence the use of materials is limited.

- Print on Demand

Design files are printed when needed due to the availability of storage space. They are saved in a virtual library, and accessibility is easy.

d. What Are The Drawbacks of a 3D Printer?

- High Energy Consumption

Printers use electricity to operate. They consume 100 times more power than traditional manufacturing methods, and costs are usually high.

- Fewer Materials

Most machines use a selection of metals and plastics since they are cheaper and easy to manage. Most raw materials are not suitable for use as they cant be recycled or reused.

- Small build size

Some printers have a small printing space, and it limits the size of print to be produced. More extensive models require large build size, and you may be required to get a massive machine or print it in small parts.

Conclusion

3D printers have brought about growth in businesses and industrial operations, and understanding them is vital. 3D printers are used in various ways, such as education, prototyping and manufacturing, health sector, construction industry, and the art field.