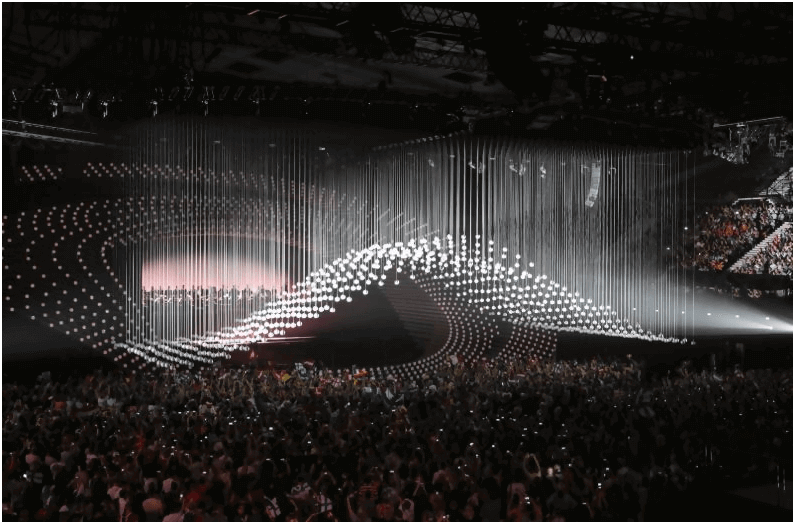

Though it has become increasingly easier to find places to buy high-quality kinetic lights, sometimes not knowing what to purchase might be the problem. Usually, this problem comes to be when you have no idea what you are going to use it for hence having not done any prior planning or study. If you are looking to invest in kinetic dance lights, ABD Stage Light or any other type of lights, then there are several steps to take to ensure that you purchase what suits your needs. Below are 5 steps to consider when choosing kinetic lights.

- Application Of The Kinetic Lights

When deciding what to purchase, the first aspect to consider is the application of the kinetic light system. Often, there are different kinds of systems depending on the area it’s supposed to cover. As it will have a significant impact on the effectiveness of the display system, take time and consider if you want to use it to portray a specific atmosphere or for a spectacular display.

- Kinetic Lights Output

Going in hand with the area of coverage is the luminance of the kinetic light fixtures. The output usually dictates how much lighting you will get. As expected, it is highly depended on the number of diodes. Not considering the overall light output will put you at risk of investing in a light fixture that is dim and ineffective hence giving off a dull color. Additionally, consider the CRI of the kinetic lights to have a sharp contrast that you can easily adjust.

- Kinetic Lights Colors

Different kinetic lighting software enables you to set the environment and mood that the kinetic lights will display. Cooler temperatures like blue encourage a calming effect. On the other hand colors like white promote a calm and inviting environment even as green and purple portray a celebratory mood. Additionally, when you consider color, keep in mind that you can invest in kinetic lights that have an edge color distortion feature that allows cool after effects.

- Kinetic Lights Power Options

For easier control of the kinetic light descent feature and adjustment of lights from one central place, consider the ideal power options. Often, kinetic lights can either be run on batteries or be plugged into a direct power source. When choosing, factor in if you will always have access to a power source socket to operate. Also, consider if at any one time you will need to be portable when controlling the kinetic lights.

- Kinetic Lights Extra Features

Finally, consider any additional features that you might want to use in connection with the kinetic lights. Even though most kinetic lights system is universal and compatible with extra features like LCD screens, battery life indicators, dimmers, and bi-colors, some systems aren’t supported. So take time and countercheck if the system you want to invest in supports those extra features.

Conclusion

Overall, even as you narrow down your choices, invest in unique kinetic light software like the ABD Stage Light, it’s wise to focus on your specific needs. In all, don’t forget to consider aspects such as the beam angle or if you want a multi-chip or single-chip kinetic lights fixture. Doing so will allow you to choose the right system to invest in and save you money.