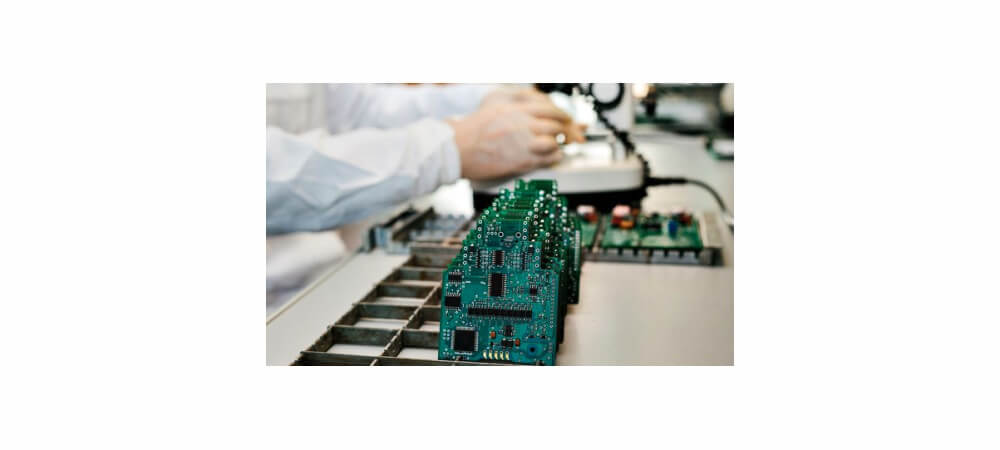

In search of a qualified and professional PCB manufacturing company for fabricating your PCB? Then you have to contact the UET PCB manufacturing service as they have the best possible manufacturing machinery and highly qualified working staff. Their professionalism and customer satisfaction sets them aside from any other PCB company. They offer not only your PCB manufacturing but also have other services to provide, such as component procurement, PCB assembling, and electronic manufacturing services. Their services are versatile and have solutions to all of your PCB or electronics related problems.

Why UET?

They can provide a solution to PCB related issues faced by industries. Whether it is any sort of electronics, medical industry, digital communication, automotive industry, new energy, or aerospace industry, they can get your PCBs or electronic products ready within time. Plus, they have 24/7 customer service available to solve your queries at any time of the day. They also have the ability to mass production of PCBs. You can get your prototype made first, test it, and get its mass production done. They can also handle the high mix, SMT, or through-hole technology, allowing you to avail PCBs of the latest technology.

PCB Manufacturing

PCBs manufactured by them are of the highest quality according to the customer’s requirements. For the ideal optimization of your solutions, they can provide you rigid-flex/flex, standard FR4, High-speed/ microwave/RF, hybrid, and aluminum boards. They are cost-effective boards that will not only enhance the performance of your products but also make sure your desired needs are met. Your expectations are fulfilled, and your device works perfectly after installing these boards. And yes, deadlines are strictly followed so that you can have your PCB or electronic item ready within the decided time.

PCB assembly

Turnkey PCB manufacturing company is one of the most advanced and highly qualified companies that is leading in the PCB assembly services. They have the capability to do PCB assembly, such as mixed board assembly, through-hole assembly, prototype board builds, package on package, SMT assembly, and BGA assembly with X-ray inspection. They can complete any type of PCB assembly project, including full PCB assembly projects. There have professionals who are experts in PCB designing, component sourcing, PCB manufacturing, and testing. They do on-time delivery, offer services if you face any problem while using PCBs and warranty support.

Electronic Manufacturing

They are providing electronics solutions to various markets. Along with PCB manufacturing and assembly of electronics, they also offer component procurement, wire harness assembly, and box builds assembly services to their customers. After seeing and using their manufactured electronics, the only words that will come into your mind are “fast turnaround,” “high reliability,” and “precision.”

Quality Checks

To ensure their products’ quality, full flesh quality testing and checks are made before delivering them to the customers. Their PCBs and electronic items are ISO 9001:2015 certified to meet the requirements of your design. Their every PCB assembly, prototype and design process meet the regulations of IPC-A-610 Class 2 and Class 3.

So, next time if you want a PCB solution for your product, request them to get your high-quality PCB solution ready within no time with affordable rates.